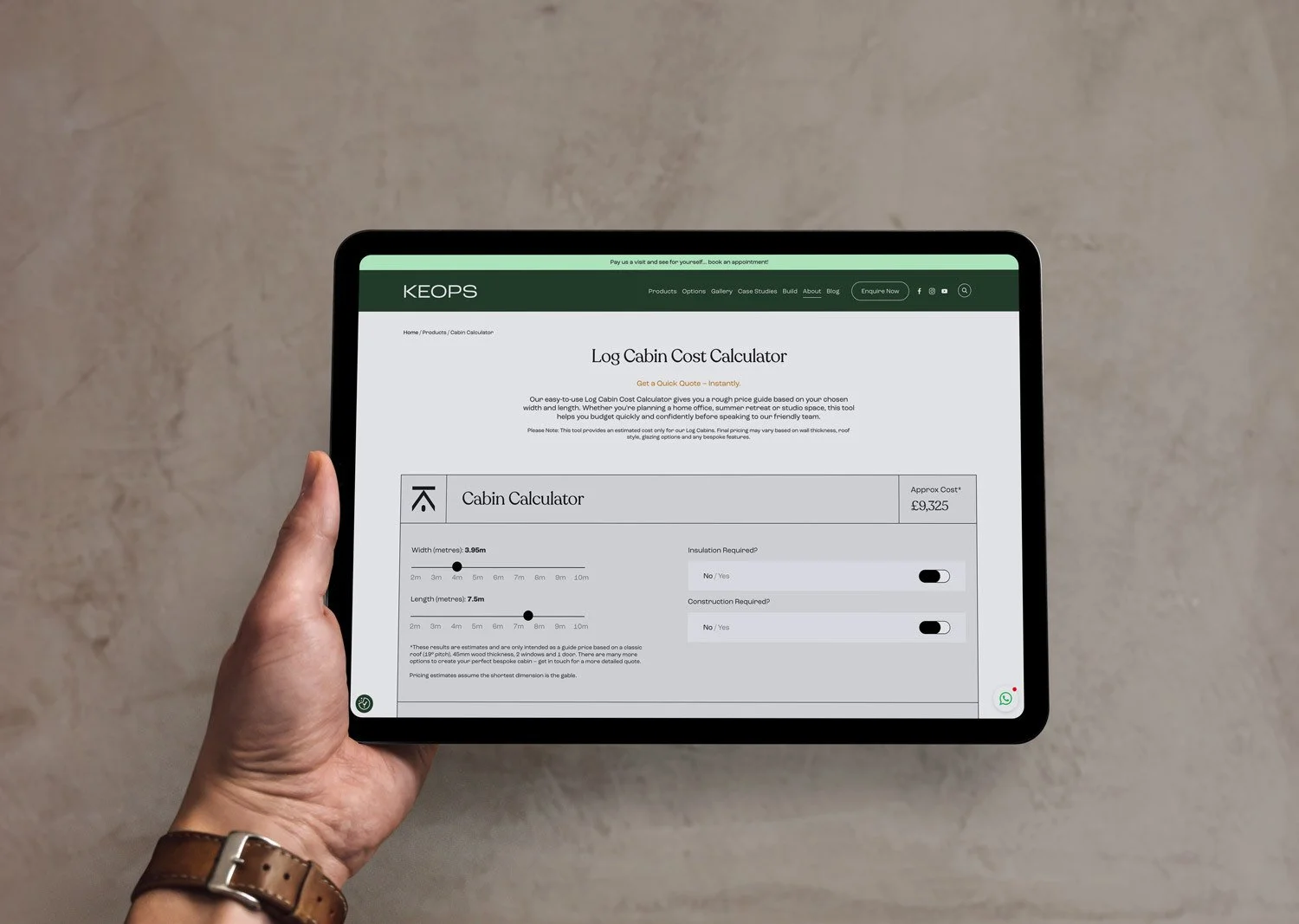

About Us

We are Keops.

Our passion? Crafting amazing cabins for work, play, and leisure that you'll love, (and that will make your neighbours jealous!)

We truly believe in our motto: Design. Build. Inspire. Creating spaces for everyone and everything, where quality and timeless beauty come together, turning dreams into a tangible reality.

We're devoted to designing beautiful and functional spaces, sourcing the best Scandinavian pine and building with care and precision so you can count on our exceptional products to be with you forever.

The Legacy of Generations.

Keops was established over twenty-three years ago and has been a family run business from its first day. Every customer becomes an extension of the Keops family, with each of our cabins carefully considered and hand-crafted with a personal touch. Our entire team of designers, engineers, sales advisors and after-sales technicians are all under one roof, working together to craft the best quality, best value and most flexible log cabins on the market.

Keops has evolved from an engineering background into designing and building bespoke creations, crafted with precision and passion. Each Keops cabin is a testament to our unwavering commitment to quality.

As a small company, we take pride in our products and developing relationships with our customers, and we love nothing more than seeing our client’s visions come to life. We take you with us through the process, from idea generation to the final finishes. Prioritising your ideas and specifications, ensuring openness and honesty and immediate solutions if we face any difficulties.

Investing in a Keops cabin is investment in a beautiful space that will be cherished by your family for generations to come, the same way we cherish Keops.

Why not let us build your log cabin for you?

We can construct your cabin for you and offer a Nationwide and European service.